CODESYS supports the most common standard communication protocols for data exchange between controllers, such as OPC UA. In addition, Ethernet-based fieldbus systems such as PROFINET or EtherNet/IP™ make it easy to exchange data between controllers by implementing master and slave functions. These solutions come with the advantages of standardization. However, they entail the disadvantage of large overheads during data transmission.

Network variables

The so-called network variables make things easier and faster: In order to use this proprietary protocol, global IEC 61131-3 variables are declared in a special sender object. In addition, the object is configured using information about the type of transmission, such as port address, data compression or checksum. The user can specify whether the transmission is to take place cyclically, on change or after an event. The corresponding receiver object only needs the data list exported by the sender and can then connect to the sender. Thus, the variables created in the transmitter object are transmitted via Ethernet UDP to connected controllers and can thus receive the data. The desired control values can be divided into several network variable lists (NVL) for transmission or reception.

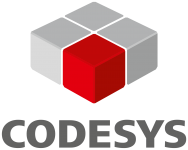

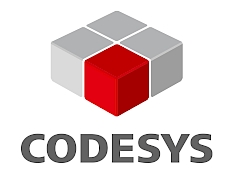

Data Sources

For the visualization of control data, you can also use a proprietary connection instead of an OPC DA/UA connection. Prerequisite: You use CODESYS HMI as visualization client.

Several objects ("data sources") which simultaneously connect to several controllers can be defined in the Data Source Manager. With one display device and installed CODESYS HMI, the control data of various small devices can be read out and displayed. The source controls remain practically free from CPU or memory load. The object "Symbol Configuration" publishes the data on the source controllers. This allows the data to be divided into different objects as required. As soon as the connection to the source control has been established, you can browse through the exported variables and use them.

How can you use proprietary communication protocols?

- Use CODESYS-compatible PLCs with Ethernet port. Millions of CODESYS-compatible single devices and over 1,000 different device types from more than 500 manufacturers offer you a large range of hardware for your automation projects. CODESYS Inside offers a selection of manufacturers that offer CODESYS-compatible devices. Alternatively, you can use the CODESYS Control SoftPLC systems from the CODESYS Store and install them on standard device platforms. The network variables can be used immediately.

- Purchase CODESYS HMI SL in the CODESYS Store. The source data can be used immediately via the Data Source Manager.

Products

CODESYS offers seamlessly integrated communication protocols for a wide variety of interfaces and requirements.

OPC Server

Standard Interface to access the IEC 61131-3 process data of a controller via Open Platform Communications.

OPC UA

Standard Interface for Communication in Smart Factory and Industry 4.0 Systems

PLCHandler

Compact software interface (API) for easy access to the PLC variables in CODESYS controllers from external systems

BACnet

Configurator and protocol stack fully integrated in the IEC 61131-3 Development System

Serial interfaces

Although today almost every industrial controller has an Ethernet connection, serial interfaces are still installed in many industrial devices. This allows, for example, for the connection of appropriately equipped sensors and actuators or extensions.

Standard Ethernet

How does CODESYS communicate via Ethernet? How can I send and receive data from a CODESYS-compatible PLC via TCP or UDP? How can I realize data exchange from the PLC application?

Fieldbus systems and Industrial Ethernet

Sensors and actuators/actuators for processing control tasks can be separated from the controller via fieldbus and Ethernet systems with industrial communication protocols.

IIoT libraries

All IoT communication protocols can be implemented and used on different transmission media via software.

Other communication options

If a physical port is available on a controller, communication protocols can usually be implemented simply via software, either as part of the IEC 61131-3 control application or as separate library modules. Data exchange is performed by explicitly calling functions or function blocks as part of the logic control.